Problem & Solution

❌ The Problem

- Most people breathe incorrectly — shallow, fast, chest-based

- Breath governs anxiety, cognitive performance, energy, creativity

- Existing solutions (apps, mindfulness) are passive — no measurable training

- No hardware builds breath strength like physical training builds muscle

- $89B wellness market, but nothing targets the root: physiology

✓ The Solution

- Nasal wearable with medical-grade silicone — comfortable for daily use

- Sensors measure airflow, pressure, tempo in real-time

- AI coach provides adaptive training, form correction, motivation

- Longitudinal tracking shows measurable improvement

- Daily ritual that builds discipline and physiological control

More Than a Device

The Peloton for Breathing

ÆOESS isn't a meditation app in hardware form. It's physical, measurable, repeatable performance training — treating breath the way a gym treats muscles. The diaphragm is muscle tissue. It responds to progressive resistance.

The device captures airflow patterns through dual optical sensors. The AI coach interprets patterns, detects dysfunction, and guides users through personalized training cycles.

Long-term vision: An always-on companion that understands your physiological state — stress patterns, emotional regulation, performance readiness — and helps you consciously control what was previously unconscious.

🧊 Go-to-Market: Wim Hof Community First

The Wim Hof Method community represents the perfect initial market — highly engaged practitioners who already understand the value of breath work but lack tools to measure and optimize their practice.

Hardware Development

The journey from concept to working prototype involved multiple iterations of device geometry, sensor integration, and electronics design.

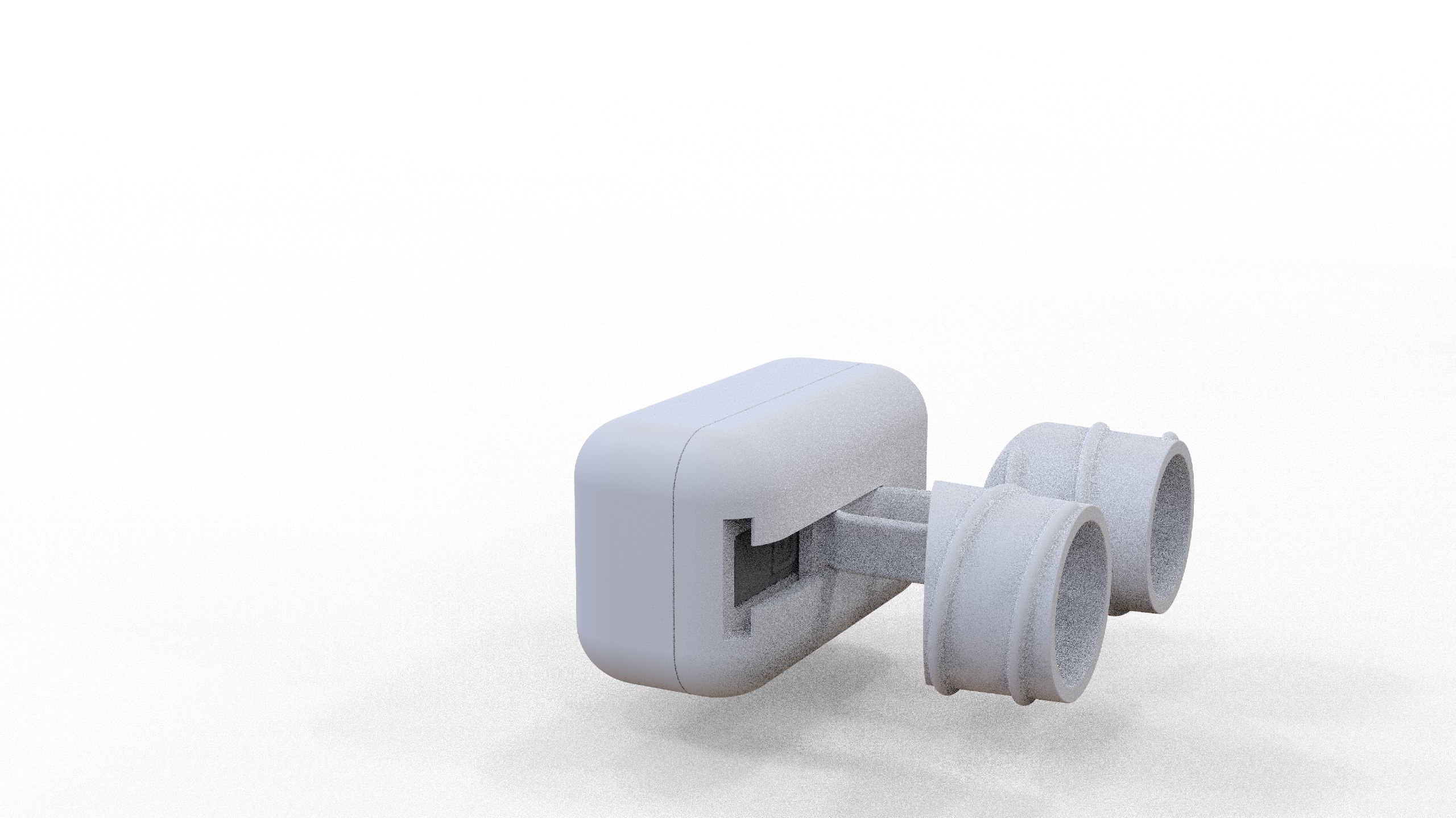

MVP v2 — Core Assembly

Early prototype with sensor integration

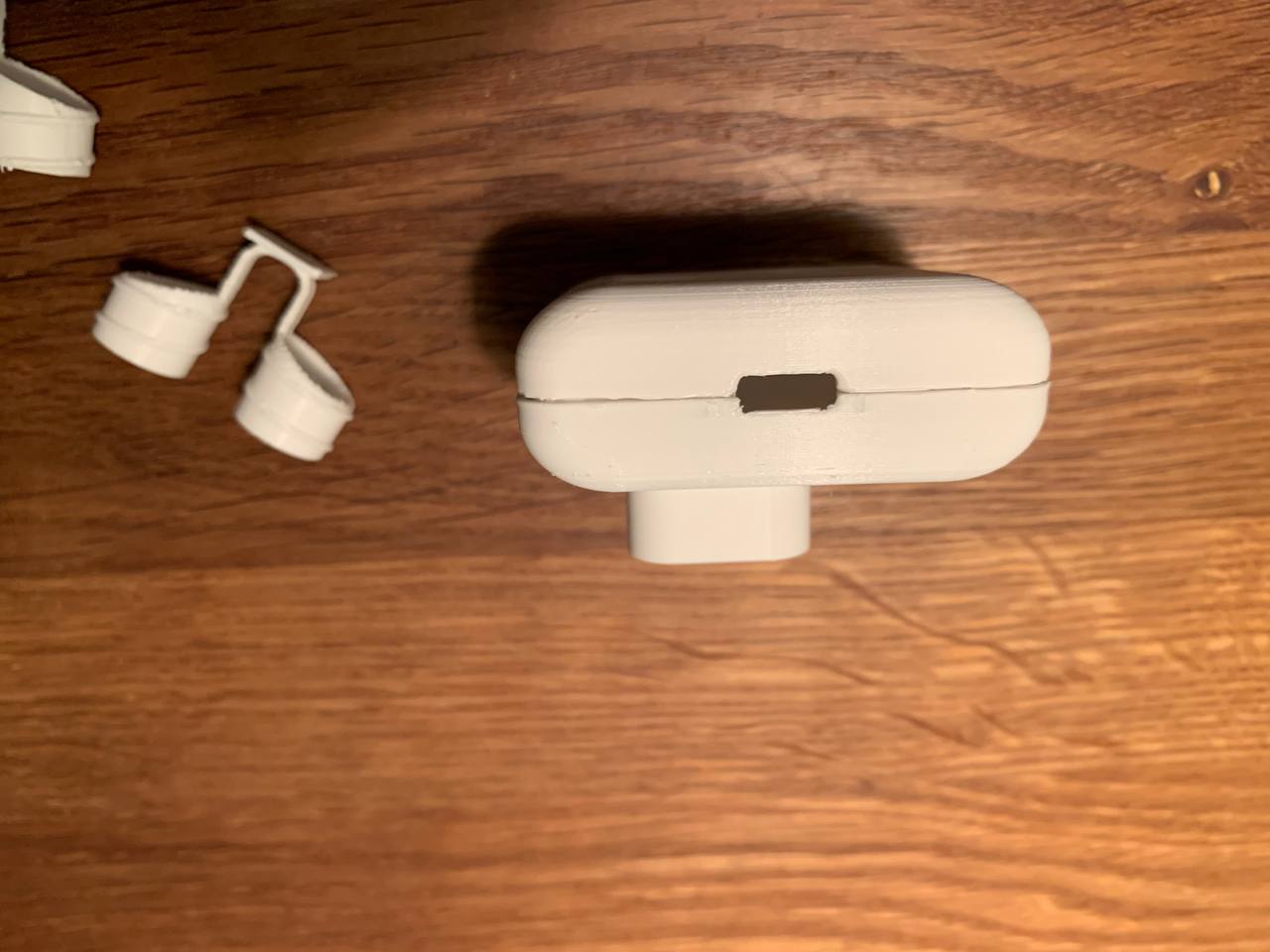

Form Factor Iteration

Device + charging case ergonomics

Case & Nasal Inserts

Silicone inserts with carrying case

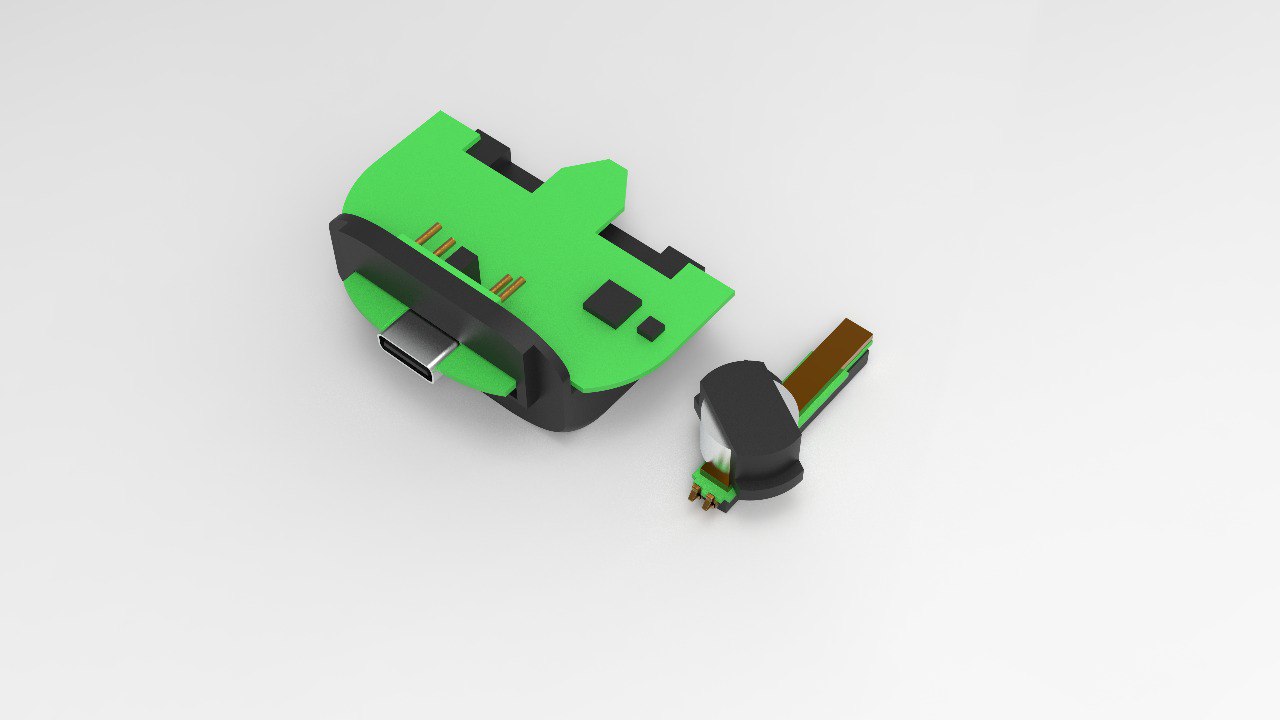

Sensor + MCU Integration

Compact electronics for nasal form

Electronics Layout

PCB design for miniaturization

Late-Stage Prototype

Near-final form with integrated sensors

🔧 Mechanical Design

- Resistance mechanism calibration

- Nasal insert ergonomics & materials

- Airflow channel optimization

- Compact form factor for daily use

⚡ Electronics

- Dual optical airflow sensors

- Breathing-sensitive microphone

- Bluetooth Low Energy communication

- Battery management system

From MVP to Production

Two major design phases: functional MVP for validation, then production-ready design balancing aesthetics with manufacturability.

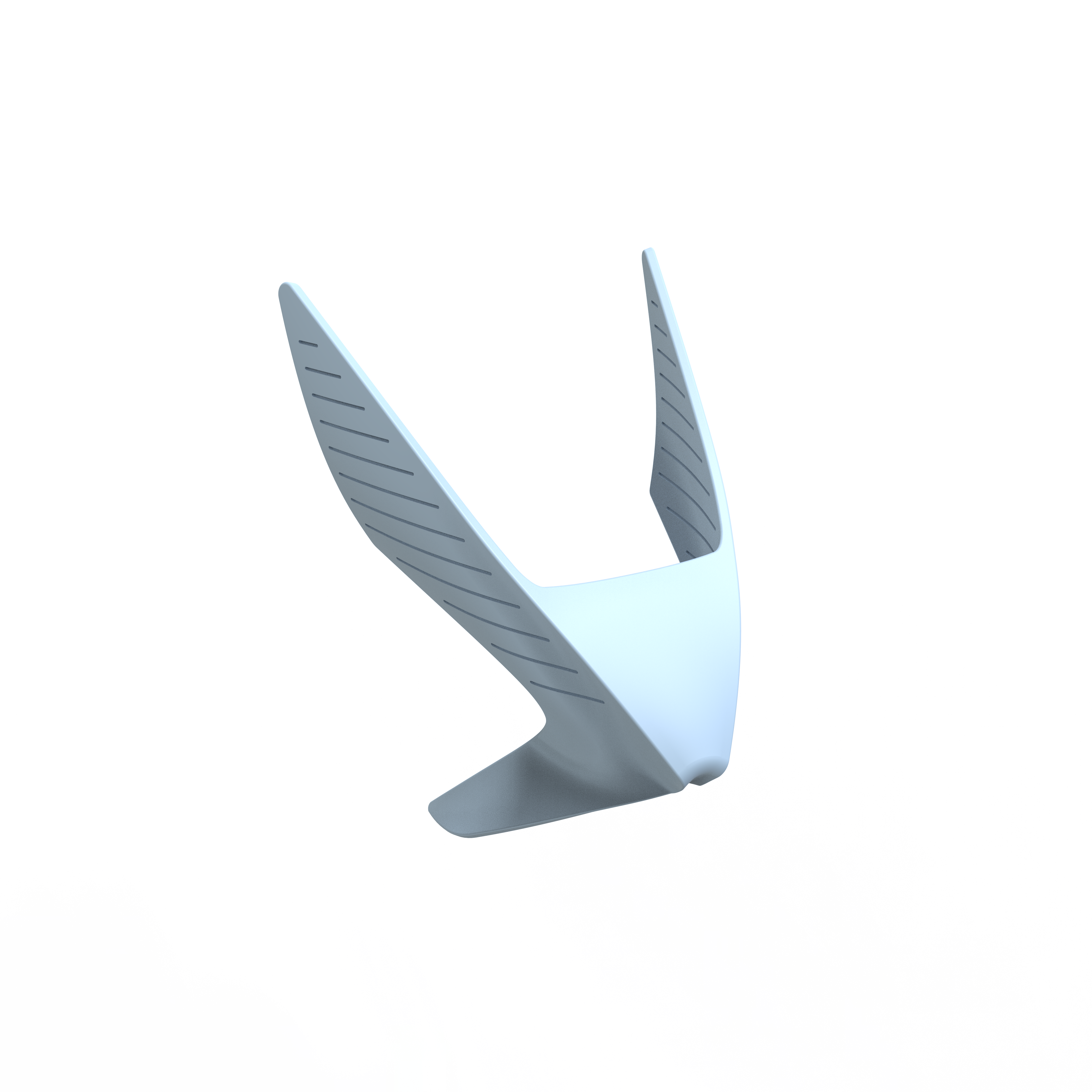

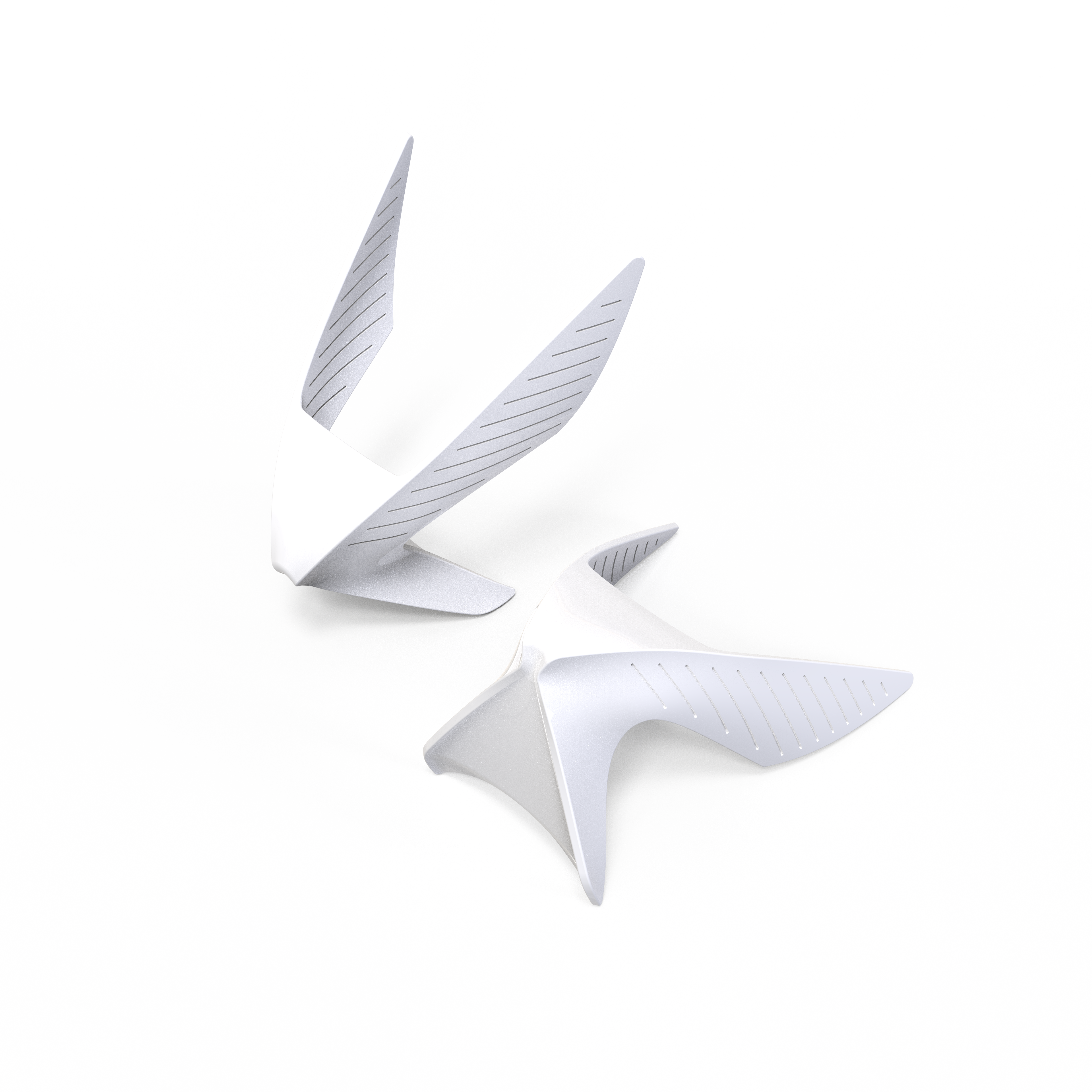

Production Design — Multiple Angles

Final form factor from different viewing perspectives

Technical Aesthetic

Tech-forward design language with visible precision

Form Exploration

Organic curves inspired by breathing rhythms

Internal Components

View showing sensor placement and design details

AI Coach System

Hardware alone isn't enough. People need guidance, motivation, feedback, and personalization. The AI layer transforms raw sensor data into actionable coaching.

🎯 Real-Time Guidance

- Voice-guided breathing exercises

- Form correction during sessions

- Pace and rhythm calibration

- Progressive difficulty scaling

📊 Pattern Recognition

- Detect breathing dysfunction

- Identify stress patterns

- Track improvement over time

- Personalized recommendations

Development Journey

Month 1-2

Concept & Research

Explored resistance breathing mechanics. Researched sensor options, airflow measurement techniques, and competitive landscape.

Month 2-3

MVP Prototyping

Built early MVP hardware with pressure sensing. Tested nasal insert geometries. Integrated sensors with microcontroller.

Month 4-5

Electronics & App Architecture

Developed BLE communication protocol. Designed app architecture and data pipeline. Built breathing pattern analysis logic.

Month 5-6

Production Design & Pitch

Commissioned professional industrial design for production. Created comprehensive pitch deck. Project paused to focus on Evatar.ai.

What Got Built

Resources

Investor Pitch Deck

Complete deck with market analysis, product vision, and strategy

Product Website

aeoess.com — landing page and brand presence

Brand Identity Guide

Logo, colors, typography, and applications

Design Concepts

Early brand directions explored

Respiratory Signal Research

Mathematical modeling of breath-to-signal processing

What I Learned

This was my first hardware product — taking an idea from napkin sketch to working prototype, industrial design renders, and investor-ready pitch.

Hardware requires different thinking than software. Physical constraints, manufacturing tolerances, and supply chains add complexity that doesn't exist in code.

The gap between "prototype works" and "manufacturable product" is enormous. What works in a lab often fails at scale.

Industrial design isn't decoration — it's core to user adoption. People won't use something daily if it doesn't feel premium.

Sensor selection and signal processing are their own deep domains. The "easy" part turned out to require significant research.

Sometimes the timing isn't right, and that's okay. The IP and learnings aren't going anywhere.